Timing Belt Degradation in the 300 Tdi

Having seen timing

belts break on new vehicles with only 18000km on them, and having the 4th

fitted to my own vehicle at 104000km, I was interested to see what a belt with

3700km looked like after being fitted.

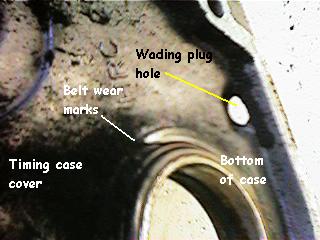

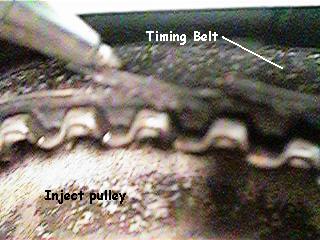

The first surprise

was found when the front timing cover was removed.

Given the problems

related to timing belts, it became a habit of checking for belt debris via the

front wading plug. As can be seen in the above picture, very little debris

comes far enough down to be “inspected” at the wading plug.

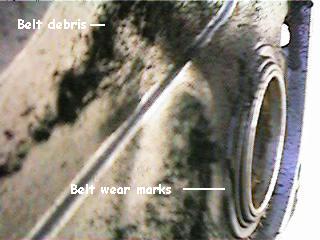

The close up view

shows that the area around the wading plug is relatively clean. A closer

examination also shows the wear in the timing case cover from previous

“migrating” belts.

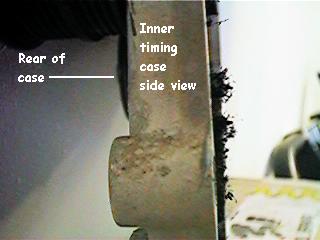

This next view of

the inner timing case shows how the debris is well clear of the area around the

wading plughole. While inspecting for debris via the wading plug may make you

feel comfortable it is not a clear representation of the status of the belt.

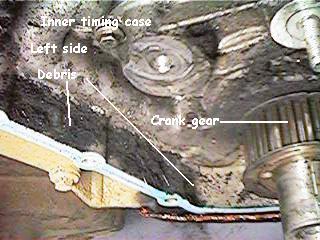

Inner timing case,

showing collected debris. It should be noted that this is from an engine, with

a belt fitted less 4000km before this inspection. The pictures also show the

modified crankshaft gear fitted by local dealership as part of “timing belt

fix”.

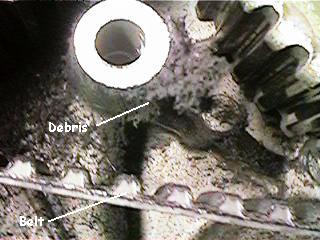

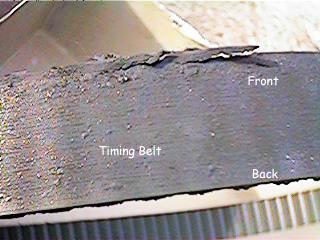

The actual belt is

shown in this next photograph, and is shown prior to removal.

While not well

focussed the next picture shows the belt beginning to fray-possibly from

running against the front of the edges of the modified crankshaft gear?

The pen points to

one of three fray points on the timing belt.

Close-up views of

belt debris at an oblique angle.

The side view

shows the matted nature of the belt debris. It should be noted that this

material has stayed in this formation, after the inner timing case was removed

from the engine. This process involves separating this component from the front

of the engine after removing the belt and a number of gears.

Given that the

belt is a timing belt, one wonders what impact this debris has if it falls onto

the belt when in operation.

The author and

others have noted that the 300 Tdi has the occasional habit of small power

surges at around 2000 rpm, and this could perhaps be due to either debris

falling onto the belt (it should be remembered that both sides of the belt are

used) or movement of the belt causing changes in the injector pump timing.

Prior to removing the belt it was interesting to note the effect of any small

deflection on the belt had on the injector pump.

What’s all the fuss about belts?

If your trouser

belt breaks, not a real drama, except that you may cause yourself some

embarrassment, and or find yourself the centre of unexpected attention.

If your timing

belt breaks, then this is a real drama. Depending on where you are and what you

were doing when it breaks will determine the extent of the drama.

A broken timing

belt means your engine is inoperable.

No matter how

quickly you react to the break, and it happens quickly and quietly, you will

not prevent some engine damage by pushing in the clutch to prevent the engine

from being “driven” by the drive train. I am unaware at this stage what happens

in an automatic.

If you were

descending a steep hill, you have suddenly lost all engine braking, power

steering, and your brakes are now no longer power assisted, and it will take

longer to stop. Besides, having been trained in the correct 4WD techniques for

steep descents, you were relying on the engine, and not your brakes.

If you were

cruising down the highway, you have no power, no power steering, and your

brakes are now no longer power assisted, and it will take longer to stop.

At this point your

vehicle is disabled and you will need to either be towed (and this can be

strenuous work for the driver as the power steering and power assisted brakes

no longer work) or have the vehicle taken to the nearest garage by flat top

truck. There is nothing you can do, even if you had a spare timing belt, all

the tools and 4-5 hours to fix the problem.

So what happens when the timing belt breaks?

This is classic

question that prompts the asking of another classic question; “How long is a

piece of string?”

The answer lies in

an understanding of the function of the timing belt, and will vary at the time

it breaks, the engine rpm etc.

The timing belt is

responsible for ensuring that the pistons, injector pump, inlet and exhaust

valves are in the correct place of the 4-stroke cycle at the appropriate time.

If not there is a real risk of collisions between these components, and as this

is outside the purposes for which they were intended, they and other parts of

the engine will be damaged.

The extent of the

damage is difficult to predict, and will only be known once the garage has

inspected the engine.

If you were lucky

the damage may be restricted to belt breaking, and as a result only the push

rods were damaged. These appear to have the amazing ability to bend almost in

an extended “s” shape.

If we were to

simply replace the push rods and timing belt, and remove the head to ensure

that none of the valves had collided with any of the pistons, we would have a

shopping list something like this:

Timing belt $165.68

Push rods 8 x $15.96 $127.68

Head Gasket $82.52

Subtotal $375.88

Oil $60.00

Oil filter $22.45

Parts and consumables $458.33

To this we now add

labour costs, and for this exercise we’ll allow 5 hours. Depending where the

work is carried out i.e. dealer or independent service agent this will add

between $250 - $375.

No allowance has

been made for transportation costs back to the point of service, as this will

depend upon the location, and wether or not you have some form of auto club

insurance to cover this recovery.

This gives a cost of

between $708 and $833 for a “good break”. In the case of experiencing more

damage both labour and parts costs will be much higher.

Can’t I simply change the belt on a preventative manner?

Yes you can, but

this will cost between $360 - $460 depending on where the work is done. The

original replacement period has been changed from 100,000 km to a range

somewhere between 60,000 km and 100,000 km depending on how the vehicle is

used.

Changing the belt,

or even fitting the upgrade kits, doesn’t give an absolute guarantee that it

won’t fail prematurely. The photos above are from a belt that was changed by a

local dealer, and has done less than 4000 km, and was fitted with all the

manufacturers’ timing belt modifications.

Can I have another look at that belt?

Here are some

shots taken after the belt was removed from the engine. You can now get a

clearer picture of the shredding process as it starts. Remember this is a belt

with 3700 km of use.

Here is a view

from a different angle.

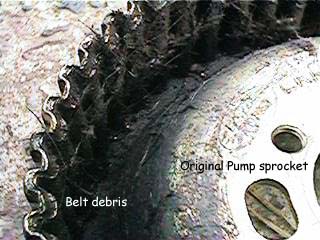

It was also interesting

to see the manner in which the injector pump sprocket collects the belt debris.

A cynic might ask if this was design foresight or simply good luck!

Anyone who has

worked at a side show may think this is a photo of one of the machines used to

make candy floss (aka fairy floss).

OK, so let me guess, you just happen to have the solution?

Indirectly, yes I

do. I have been investigating this problem for a while, as I like my 300 Tdi Discovery.

I recognise it has some interesting quirks, but with the exception of the

timing belt problem, none of these would be as disabling or expensive.

I don’t want to

upgrade to the new model, and I am a committed Land Rover user, and wouldn’t

consider any of the other manufacturers. As I plan to keep my “disco” for quite

some time I was determined to find a solution, based on good engineering, and

accessible to the general public. I also wanted something that I could fit

myself.

The solution was

found in England, in the form of the timing gears from Zeus. I researched their

product extensively, and as a result have taken responsibility for offering

these products in Australia and New Zealand. I have fitted the gears to my car,

and the data from the pre and post installation dynometer studies are shown below.

You remind me of the advertisement for a certain

electric shaver.

Understandable

comparison, but there are differences.

That gentleman was

so impressed he bought the company, as he had the obvious ability to do so.

While I don’t have

his extensive resources, I am putting my money where my mouth is, and will be

selling and supporting the products in this market.

I accept that the gears work, but I don’t have the

time to fit them.

YiCaN Pty Ltd

recognise that not everyone will want to fit his or her own gears for a number

of reasons. There are some special tools required, but even these, can be made

by the vehicles owner. Therefore in anticipation of this situation, approved

fitment centres are being established, by cooperating with local companies with

4WD and diesel experience. We are starting in Melbourne, where we are based,

and will cover other cities and regions in an orderly manner.

For those people

wanting to fit their own gears, step-by-step instructions are available, and

the special tools may be made available for hire to Australian customers.

What did you find in the dynometer studies?

Rather than describe what we found let me show you the results. The graph confirms, and quantifies, the increase in power at the low end. What was surprising was the size of this increase-nearly 10 kW at around 65kmh.

As expected the extra power increase translates into improvements in fuel economy. Typically we are finding an extra 150 km range is added to each tank of diesel. The best range so far in the Discovery, with a mixture of town and highway driving is 909 km from one tank!

In both tests the engine was "tuned" with the engine being set to TDC and the injector pump timing set at this point. This is the standard method of adjusting the 300Tdi engine. The injector pump was not altered in any way, and is as per standard settings for this pump. The dynometer test was carried out by the Chisholm Institute, Frankston, and the same operator carried out both tests. As such we believe this to be an independent test as it was totally under his control, including the "driving" of the vehicle on the dynometer.

It should be noted that the objective of fitting the Zeus Timing Gears was to eliminate timing belt problems and associated damage-changes to performance are simply a bonus.

Sounds good, but what do I get in a kit?

Here is a photo of the Zeus Timing Gear kit as seen from the front. This shows the system prior to the installation of the original front timing cover.

In addition to the parts shown here the kit includes: gaskets, wading plug, instructions, warning sticker, oil banjo plug, permabond, warranty form, dowels and studs. Basically, everything you need except for

oil and your own tools, to fit the kit.

The kit is shipped to you in a strengthened cardboard box, weighing about 11.0 kg. Method of delivery is usually by

Express Parcel Post within Australia, or international courier eg FED-EX for our International customers. If you have a prefered method of shipment

this can be used if required.

How do I find out more about the Zeus Gears and your company services?

Listed below are our email, fax and phone numbers, so please use whichever is the most convenient for you.